The molded pulp watch tray's construction utilizes rapidly renewable bamboo fibers, offering superior strength-to-weight characteristics compared to traditional wood pulp alternatives. This material choice provides exceptional rigidity that maintains dimensional stability even under varying humidity conditions, ensuring consistent fit and protection throughout the product's journey from manufacturer to end user. The slightly textured surface texture creates gentle friction that keeps delicate watch components stationary without requiring foam overlays or plastic clips. Strategic depth variations accommodate different component heights, from slim mesh bands to bulkier leather straps with substantial buckles, within a unified layout that maximizes space efficiency.

What We Mainly Make?

Molded Pulp Packaging

Molded pulp packaging is a sustainable packaging solution for various industries, including food, healthcare, cosmetics, household products, and electronics.

Molded Pulp Inserts

Molded pulp inserts find versatile applications across industries, including electronics, glass products, food, medical devices, and compliance with regulations.

Molded Pulp Supplies

Mold pulp products can be applied to various daily-use items, including tableware, personal care items, household goods, toys, packaging materials, stationery, and home decor.

Molded Pulp Accessories

Depending on the product's purpose, molded pulp accessories can include lids, handles, dividers, and more.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

Public Mould

Public Mould

Packaging Solutions

Packaging Solutions

3D Design

3D Design

Customized Mould

Customized Mould

Molded Pulp Watch Packaging Tray

Molded Pulp Watch Packaging Tray

The molded pulp watch tray's construction utilizes rapidly renewable bamboo fibers, offering superior strength-to-weight characteristics compared to traditional wood pulp alternatives. This material choice provides exceptional rigidity that maintains dimensional stability even under varying humidity conditions, ensuring consistent fit and protection throughout the product's journey from manufacturer to end user. The slightly textured surface texture creates gentle friction that keeps delicate watch components stationary without requiring foam overlays or plastic clips. Strategic depth variations accommodate different component heights, from slim mesh bands to bulkier leather straps with substantial buckles, within a unified layout that maximizes space efficiency.

What We Mainly Make?

Molded Pulp Packaging

Molded pulp packaging is a sustainable packaging solution for various industries, including food, healthcare, cosmetics, household products, and electronics.

Molded Pulp Inserts

Molded pulp inserts find versatile applications across industries, including electronics, glass products, food, medical devices, and compliance with regulations.

Molded Pulp Supplies

Mold pulp products can be applied to various daily-use items, including tableware, personal care items, household goods, toys, packaging materials, stationery, and home decor.

Molded Pulp Accessories

Depending on the product's purpose, molded pulp accessories can include lids, handles, dividers, and more.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

FAQs

Can I customize the interior to hold different earring styles?

Can molded pulp packaging look luxurious?

Is molded pulp safe for delicate jewelry?

Do you have standard molds available?

Do you offer design services for custom packaging?

You may like

-

Earring Packaging Pulp Molding Packaging

Regular price $0.00Regular priceUnit price / per -

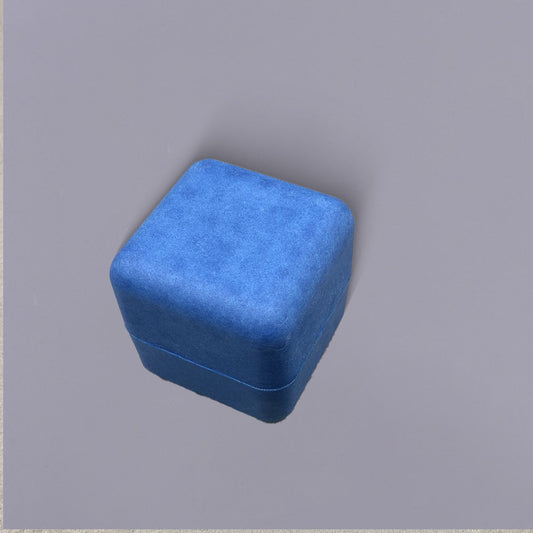

Faux Leather Texture Flip-Top Box

Regular price $0.00Regular priceUnit price / per -

Sustainable Molded Pulp Jewelry Box

Regular price $0.00Regular priceUnit price / per -

Factory Black Wet-pressed Watch Inner Tray

Regular price $0.00Regular priceUnit price / per -

Bio Degradable Molded Fiber Bagasse Jewelry Boxes

Regular price $0.00Regular priceUnit price / per -

Earrings Gemstones Jewelry Bagasse Sustainable Packaging

Regular price $0.00Regular priceUnit price / per