Crafted from compressed plant-based materials, these inserts deliver cushioning protection traditionally achieved through foam or plastic components that persist in landfills indefinitely. The rectangular format fits standard jewelry boxes and pouches while the centered cutout creates an elegant frame that draws attention to the earrings themselves. The raised edges along the perimeter add structural reinforcement, allowing these lightweight inserts to support heavier statement pieces without collapsing. Unlike synthetic alternatives that generate static electricity attracting dust to jewelry surfaces, the natural fiber composition remains neutral, keeping products pristine until customer unboxing.

What We Mainly Make?

Molded Pulp Packaging

Molded pulp packaging is a sustainable packaging solution for various industries, including food, healthcare, cosmetics, household products, and electronics.

Molded Pulp Inserts

Molded pulp inserts find versatile applications across industries, including electronics, glass products, food, medical devices, and compliance with regulations.

Molded Pulp Supplies

Mold pulp products can be applied to various daily-use items, including tableware, personal care items, household goods, toys, packaging materials, stationery, and home decor.

Molded Pulp Accessories

Depending on the product's purpose, molded pulp accessories can include lids, handles, dividers, and more.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

Public Mould

Public Mould

Packaging Solutions

Packaging Solutions

3D Design

3D Design

Customized Mould

Customized Mould

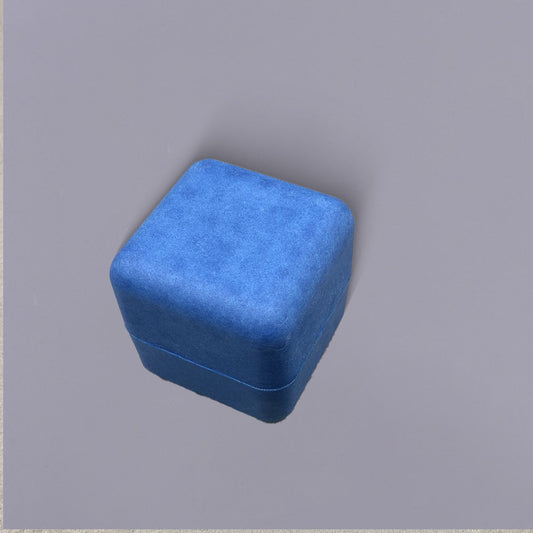

Earring Packaging Pulp Molding Packaging

Earring Packaging Pulp Molding Packaging

Crafted from compressed plant-based materials, these inserts deliver cushioning protection traditionally achieved through foam or plastic components that persist in landfills indefinitely. The rectangular format fits standard jewelry boxes and pouches while the centered cutout creates an elegant frame that draws attention to the earrings themselves. The raised edges along the perimeter add structural reinforcement, allowing these lightweight inserts to support heavier statement pieces without collapsing. Unlike synthetic alternatives that generate static electricity attracting dust to jewelry surfaces, the natural fiber composition remains neutral, keeping products pristine until customer unboxing.

What We Mainly Make?

Molded Pulp Packaging

Molded pulp packaging is a sustainable packaging solution for various industries, including food, healthcare, cosmetics, household products, and electronics.

Molded Pulp Inserts

Molded pulp inserts find versatile applications across industries, including electronics, glass products, food, medical devices, and compliance with regulations.

Molded Pulp Supplies

Mold pulp products can be applied to various daily-use items, including tableware, personal care items, household goods, toys, packaging materials, stationery, and home decor.

Molded Pulp Accessories

Depending on the product's purpose, molded pulp accessories can include lids, handles, dividers, and more.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

FAQs

Can I customize the interior to hold different earring styles?

Can molded pulp packaging look luxurious?

Is molded pulp safe for delicate jewelry?

What industries do you serve with molded pulp packaging?

Can I add my brand logo directly onto the eco-friendly material?

You may like

-

Faux Leather Texture Flip-Top Box

Regular price $0.00Regular priceUnit price / per -

Molded Pulp Watch Packaging Tray

Regular price $0.00Regular priceUnit price / per -

Sustainable Molded Pulp Jewelry Box

Regular price $0.00Regular priceUnit price / per -

Factory Black Wet-pressed Watch Inner Tray

Regular price $0.00Regular priceUnit price / per -

Bio Degradable Molded Fiber Bagasse Jewelry Boxes

Regular price $0.00Regular priceUnit price / per -

Earrings Gemstones Jewelry Bagasse Sustainable Packaging

Regular price $0.00Regular priceUnit price / per