-

Sustainable Green Perfume Bottle Container Tray

Regular price $0.00Regular priceUnit price per -

Eco Friendly Paper Molded 3C Products Packaging Insert

Regular price $0.00Regular priceUnit price per -

Green Cellulose Molded Pulp Trays For Cosmetics

Regular price $0.00Regular priceUnit price per -

Black Bagasse Molded Pulp Skincare Inner Tray

Regular price $0.00Regular priceUnit price per -

Luxury Colored Eco-Friendly Perfume Bottle Tray

Regular price $0.00Regular priceUnit price per -

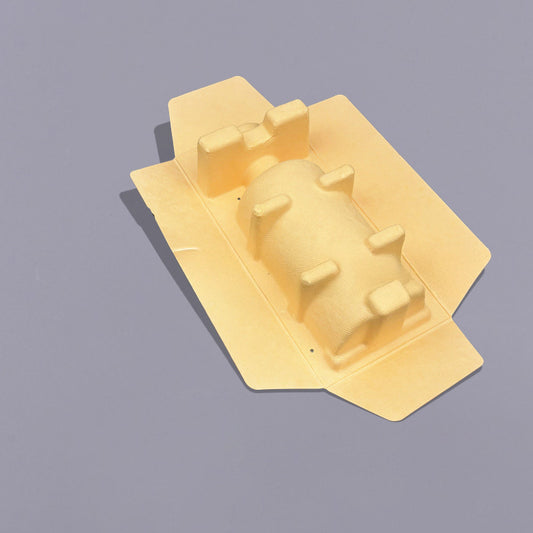

Hair Dryer Sugarcane Insert Eco Packaging Bagasse Tray

Regular price $0.00Regular priceUnit price per -

Eco Friendly Packaging Skin Care Dropper Bottle Insert

Regular price $0.00Regular priceUnit price per -

Dry Press Molded Pulp Tray For 750Ml Bottle

Regular price $0.00Regular priceUnit price per -

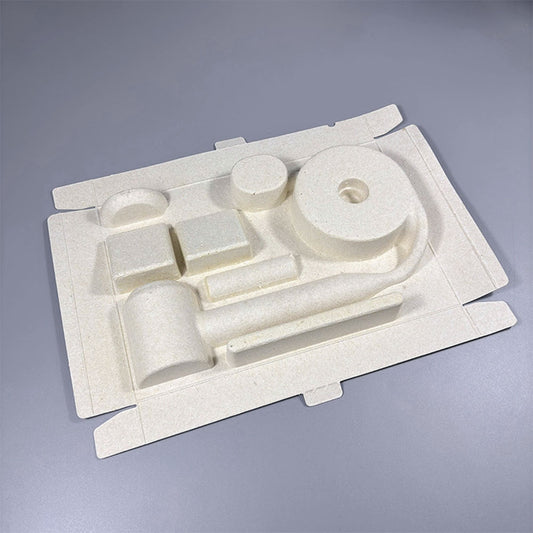

White Hair Dryer Bagasse Inner Tray Household Appliances Eco Paper Tray

Regular price $0.00Regular priceUnit price per -

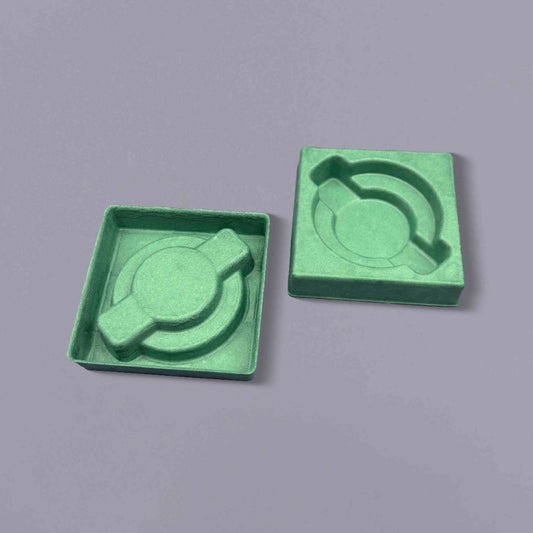

Green Face Cream Molded Pulp Insert

Regular price $0.00Regular priceUnit price per -

Zero Waste Sustainable Lipstick Pulp Insert

Regular price $0.00Regular priceUnit price per -

Wet Press Pulp Curling Iron Haircare Trays

Regular price $0.00Regular priceUnit price per -

Bio Degradable Source Green Hair Dryer Blister Packaging

Regular price $0.00Regular priceUnit price per -

Sugar Cane Bagasse Biodegradable 500Ml Bottle Blister Packaging

Regular price $0.00Regular priceUnit price per -

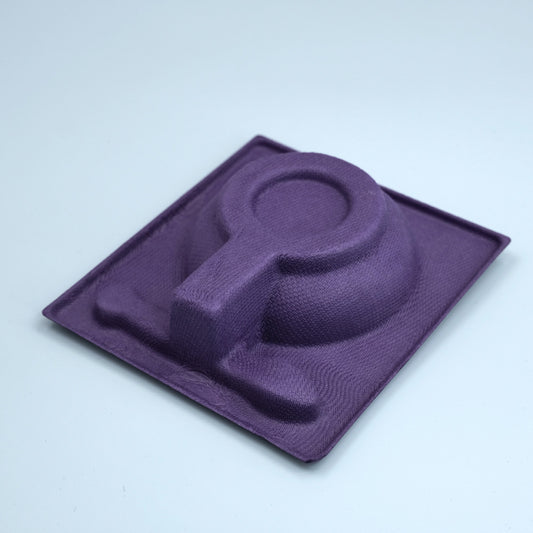

Wet Press Molding Paper Pulp Perfume Eco Friendly Inserts

Regular price $0.00Regular priceUnit price per -

Biodegradable Molded Pulp Insert For Perfume Bottle Packaging

Regular price $0.00Regular priceUnit price per -

Molded Fiber Computer Mouse Paper Pulp Insert

Regular price $0.00Regular priceUnit price per -

Biodegradable Molded Pulp Headphones Insert For Headset Inlay

Regular price $0.00Regular priceUnit price per -

Beauty Device Packaging Eco Friendly Inlay

Regular price $0.00Regular priceUnit price per -

Custom Molded Pulp Packaging Insert

Regular price $0.00Regular priceUnit price per -

Compostable Heart-Shaped Chocolate Molded Pulp Tray

Regular price $0.00Regular priceUnit price per -

Biodegradable Pulp Wrist Watch Box Case Organizer

Regular price $0.00Regular priceUnit price per -

Molded Pulp Tray Packaging For Pliers

Regular price $0.00Regular priceUnit price per -

Skincare Spray Bottle Subscription Paper Pulp Tray

Regular price $0.00Regular priceUnit price per

Ordering Process

Browse our catalog of sustainable molded pulp solutions.

Specify material, color, and quantity requirements directly.

Receive professional consultation on technical design.

High-precision production with strict quality checks.

| Item | Molded Pulp Tray | Corrugated / Paper Tray | EPS Tray (Styrofoam) | EVA Foam Tray |

|---|---|---|---|---|

| Eco-Friendly | ||||

| Logistics | ||||

| Protection | ||||

| Cost (Efficiency) | ||||

| Aesthetics |

Custom Molded Pulp Inserts for Sustainable Product Protection

Looking for protective and eco-friendly inner packaging? Otarapack specializes in molded pulp inserts that are strong, sustainable, and fully customizable. As one of the leading molded pulp packaging manufacturers, we create custom molded pulp packaging designed to securely hold products in place while reducing waste. Our paper pulp trays and inserts are made to fit items like electronics, skincare, cosmetics, and perfume—offering excellent shock resistance and a refined presentation.

Tailored for a Wide Range of Applications

Our molded pulp inserts are engineered to enhance packaging performance across multiple industries. Whether for luxury products or retail display kits, Otarapack delivers form-fitting solutions that combine structure and sustainability. As experienced molded pulp tray manufacturers, we help brands reduce plastic use without compromising protection or branding. Each insert is designed to minimize movement during transit and elevate the customer’s unboxing experience.

Eco-Conscious and Cost-Effective

Made from recycled materials, our inserts are biodegradable, recyclable, and compostable. They reflect your commitment to sustainability while reducing packaging costs and environmental impact.

What is molded pulp insert?

A molded pulp insert is a custom-shaped interior packaging piece made from recycled paper or natural fibers. It is designed to hold and protect products inside outer packaging. Commonly used in electronics, cosmetics, and fragile goods, these inserts are biodegradable, recyclable, and offer excellent shock absorption—making them a sustainable alternative to plastic.

Can molded pulp trays be recycled?

Yes, molded pulp trays are 100% recyclable and biodegradable. Made from plant fiber materials like bamboo, they can be reused or composted after use. Unlike plastic trays, they naturally break down without polluting the environment, making them an ideal choice for brands focused on sustainability.

How to make a paper pulp tray?

Paper pulp trays are made by mixing recycled paper with water to form a slurry. This pulp is poured into molds, vacuum-formed into shape, and then dried. The result is a durable, lightweight tray that offers protection and eco-friendliness. As experienced molded pulp tray manufacturers, we ensure quality and consistency.

What is paper pulp used for?

Paper pulp is used to create a wide range of packaging products like molded pulp inserts, trays, cartons, and protective carriers. It's a sustainable material commonly used in industries such as electronics, cosmetics, food, and consumer goods for both protection and presentation.

What are the components of pulp cost?

The cost of molded pulp packaging includes raw material (recycled paper), energy, water, mold design, and labor. Tooling for custom molded pulp packaging can also impact pricing. At Otarapack, we optimize each step to deliver cost-effective, high-quality solutions.

Choose Otarapack’s molded pulp inserts to protect your products—and your brand’s green image.

- Choosing a selection results in a full page refresh.

- Opens in a new window.