-

Bagasse Clamshell Eyeglass Box

Regular price $0.00Regular priceUnit price per -

Leaf Shape Embossed Perfume Packaging

Regular price $0.00Regular priceUnit price per -

Sustainable Essential Oil Dropper Bottle Packaging Box

Regular price $0.00Regular priceUnit price per -

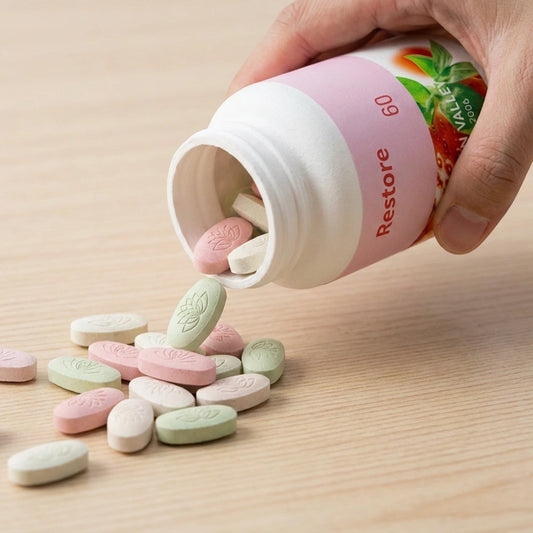

Sustainable Supplement Paper Pill Bottle

Regular price $0.00Regular priceUnit price per -

Biodegradable Cosmetic Packaging With Handle

Regular price $0.00Regular priceUnit price per -

Sugarcane Fiber Cloud Shaped Gift Box

Regular price $0.00Regular priceUnit price per -

Wavy-shaped Pulp Inner Tray for Skincare Products

Regular price $0.00Regular priceUnit price per -

Hand Sanitizer Pulp Molded Handle Box

Regular price $0.00Regular priceUnit price per -

Foil Stamping Lid Bottom Molded Pulp Perfume Packaging

Regular price $0.00Regular priceUnit price per -

Shell Shaped Biodegradable Perfume Box

Regular price $0.00Regular priceUnit price per -

[No Mold Cost] Bagasse Wireless Earphone Packaging

Regular price $0.00Regular priceUnit price per -

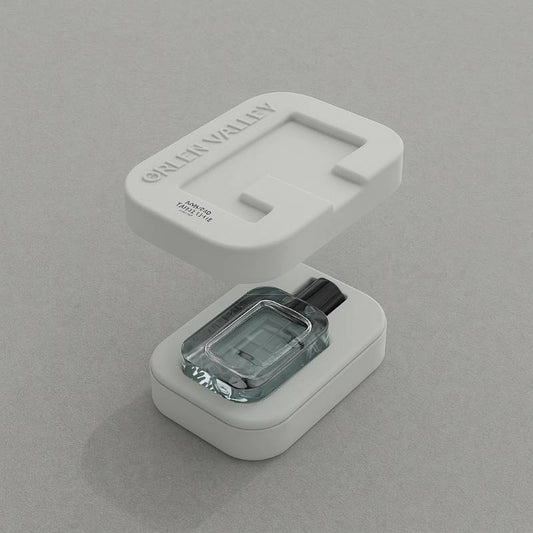

Lid Bottom Embossing Perfume Molded Pulp Box

Regular price $0.00Regular priceUnit price per -

Clamshell Cosmetic Molded Pulp Bagasse Packaging

Regular price $0.00Regular priceUnit price per -

Lotus Shaped Sustainable Perfume Box

Regular price $0.00Regular priceUnit price per -

Cupcake Shaped Bagasse Perfume Packaging

Regular price $0.00Regular priceUnit price per -

Dyed Paper Mould Tea Bag Packaging Boxes

Regular price $0.00Regular priceUnit price per -

Molded Pulp Bottle Packaging with Handle

Regular price $0.00Regular priceUnit price per -

Environmentally Friendly Skincare Bottle Package

Regular price $0.00Regular priceUnit price per -

Molded Pulp Biscuit Storage Blossom-shaped Box

Regular price $0.00Regular priceUnit price per -

Eco-Friendly Skincare Mask Ultra-Thin Lid And Bottom Molded Pulp Packaging Box

Regular price $0.00Regular priceUnit price per -

Biodegradable Embossed Patterns Paper Pulp Tea Box

Regular price $0.00Regular priceUnit price per -

Molded Pulp Bagasse Bottle Shape Shampoo Refill Packaging

Regular price $0.00Regular priceUnit price per -

Lid And Base Sugarcane Molded Pulp Glasses Box

Regular price $0.00Regular priceUnit price per -

Crater On The Moon Design Custom Molded Pulp Gift Set Packaging

Regular price $0.00Regular priceUnit price per

Ordering Process

Browse our catalog of sustainable molded pulp solutions.

Specify material, color, and quantity requirements directly.

Receive professional consultation on technical design.

High-precision production with strict quality checks.

| Four Types of Molded Pulp packaging (Data From IMFA Classification) |

|---|

Type 1: Thick-WalledThickness: 3/16 to 3/8 inch (Approx. 5mm – 10mm) Process: Made using a single mold and dried in an oven. One side is relatively smooth while the other is very coarse. Applications: Heavy-duty protection, industrial trays, edge protectors, furniture guards, and flower pots. |

Type 2: Transfer MoldedThickness: 1/8 to 3/16 inch (Approx. 3mm – 5mm) Process: Produced using both a forming mold and a transfer mold. Results in a smoother surface and a more compact structure. This is the most common type. Applications: Egg cartons/crates, drink carriers, fruit trays, and electronic product cushions. |

Type 3: Thermoformed (Thin-Wall)Thickness: 3/32 to 5/32 inch (Approx. 2mm – 4mm) Process: Crafted via multiple heated molds ("In-Mold Drying"). Produces extremely smooth surfaces and precise details with a plastic-like texture. Applications: Luxury electronics (mobile phone shells), medical trays, cosmetic inserts, and high-end disposable tableware. |

Type 4: ProcessedThickness: Depends on the base material. Process: Secondary treatments applied to the first three types, including die-cutting, printing, coating (water/oil proofing), special dyeing, or hot stamping. Applications: Custom brand packaging, retail displays, and precision gaskets requiring specialized functional features. |

Molded Pulp Packaging

Using custom tooling, we shape molded pulp into packaging and supports that fit your products precisely, ideal for perfume, cosmetics, gift sets, electronics, and other consumer goods. Compared with plastic or foam, it is lighter, recyclable, and can be made from recycled paper or sugarcane bagasse to reduce your packaging carbon footprint. We offer full OEM / ODM service for customizing molded pulp packaging, from structural design and sampling to mass production.

Explore Popular Molded Pulp Packaging Types

Our molded pulp packaging is available in a wide range of styles and finishes to suit your specific needs. Whether you’re looking for eco-friendly elegance or robust protection, there’s a pulp solution for every application. Each design is optimized for both durability and the modern unboxing experience.

Color Options

* White: Clean, modern, and ideal for premium or cosmetic packaging.

* Natural: Earthy, unbleached tones for a rustic, eco-conscious look.

* Custom Colors: Achieved through dyeing during the pulping process or surface printing—perfect for brand consistency.

Surface Finishes

* Silkscreen Printing: A traditional technique transferring ink through mesh stencils onto pulp surfaces. Offers high color saturation and strong coverage, ideal for simple patterns and large color blocks. Cost-effective for high-volume production.

* Embossing/Debossing: A pressure-based technique that raises (embossing) or recesses (debossing) specific design elements into the surface. Eco-friendly and ideal for subtle branding and elegant detail—no inks or foils needed.

* Label: Applies pre-printed labels using various materials like paper or film. Flexible solution for information updates, multi-language versions, and seasonal packaging with controlled costs and easy implementation.

* Foil Stamping: Heat-transfers metallic foil to create luxurious gold, silver, or colored finishes. Produces precise, fade-resistant patterns with premium appeal. Widely used for high-end branding and gift packaging applications.

Widely Used Applications

- * Sustainable Cosmetic Packaging

- * Sustainable Electronics Packaging

- * Sustainable Food Packaging

- * Sustainable Gift Packaging

- * Sustainable Supplement Packaging

- * Sustainable Houseware Packaging

- * Sustainable Clothing Packaging

- * Sustainable Glasses Packaging

- * Sustainable Perfume Packaging

- * Sustainable Coffee Packaging

- * Sustainable Jewelry Packaging

- * Sustainable Eyeshadow Palette

Custom Molded Pulp Packaging for a Sustainable Future

Looking for the trustworthy molded pulp suppliers for your packaging needs? You’re in the right place! At Otarapack, we are one of the leading molded pulp packaging manufacturers committed to delivering eco-conscious solutions without compromising on style or functionality. We specialize in custom molded pulp packaging and pressed paper pulp boxes, crafted to match your unique brand identity and product dimensions. Whether you're launching a premium product line or scaling sustainable operations, our paper pulp packaging offers the perfect blend of durability, innovation, and environmental responsibility. Designed for recyclability and biodegradability, our molded pulp solutions help you lower your carbon footprint while elevating product value.

Industry Applications of Molded Paper Pulp Packaging

Otarapack leads the way in molded paper pulp packaging innovation, offering smart, sustainable alternatives across a wide range of industries. Our pulp packaging is trusted by brands in perfume, skincare, electronics, gourmet food, and luxury jewelry—industries where both protection and aesthetics are critical. Each solution is engineered to meet specific needs, from impact resistance to unboxing experience, all while minimizing environmental harm. As a future-focused pulp packaging supplier, we provide molded packaging that aligns with modern consumer values.

Reliable Mold Fiber Packaging Suppliers

Otarapack is committed to building a greener future with packaging that goes beyond aesthetics. Our best bio-based pulp and paper supplies are designed to replace traditional plastic with eco-friendly alternatives. All our custom molded pulp packaging is made from renewable raw materials and is 100% biodegradable and compostable—perfect for brands looking to reduce plastic use and environmental impact. Unlike conventional packaging, our solutions break down naturally, leaving no harmful residue behind.

How is molded pulp packaging made?

Molded pulp packaging is made from recycled paper or natural fibers like sugarcane bagasse, wheat straw, or bamboo pulp. The raw pulp is mixed with water and then shaped using heated molds, forming strong and protective pulp mold packaging structures suitable for various applications. This process is efficient and environmentally friendly, making it a top choice for eco-conscious brands.

Can molded pulp be recycled?

Absolutely! Molded pulp is 100% recyclable and biodegradable. After use, the packaging can return to the recycling stream or decompose naturally without harming the environment—reinforcing your brand’s commitment to sustainability.

What is molded cardboard packaging made of?

Eco packaging like ours is crafted from renewable resources and post-consumer waste. As a trusted pulp packaging supplier, we ensure every box is made using high-quality, compostable materials, combining strength, flexibility, and environmental responsibility.

Explore a smarter way to protect your products and planet with our molded pulp solutions!

- Choosing a selection results in a full page refresh.

- Opens in a new window.

![[No Mold Cost] Bagasse Wireless Earphone Packaging](http://www.otarapack.com/cdn/shop/files/standard_mold_sustainable_bluetooth_earphone_box.webp?v=1762911102&width=533)