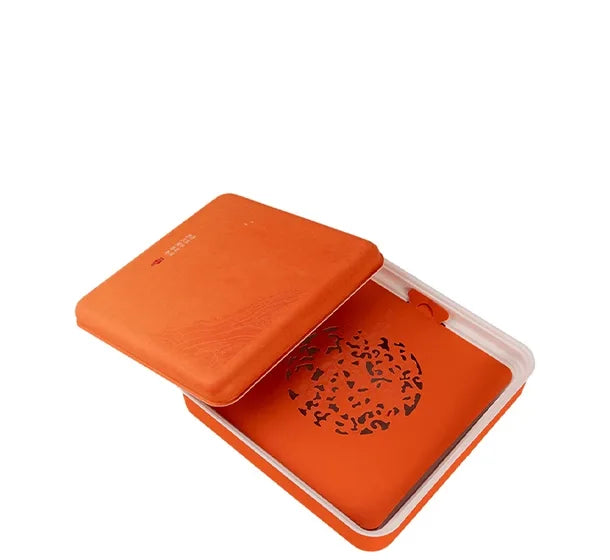

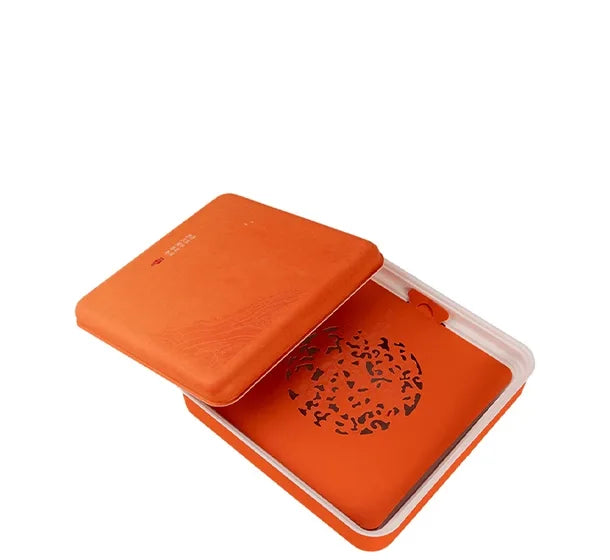

Polygonal Geometry Meets Fiber Precision Engineering

This sustainable tea cake packaging employs a precision-molded polygonal architecture that mirrors the geometric harmony found in traditional ceremonial vessels. The twelve-sided perimeter—each facet measuring 62mm in width—creates a softly angular silhouette that distinguishes premium compressed leaves from mass-market blends while maintaining structural integrity during stacking and transport. White bagasse fibers are wet-pressed at 4.2 MPa to achieve a uniform wall thickness of 3.8mm, generating sufficient rigidity to protect delicate pu-erh cakes from humidity fluctuations without requiring plastic lamination. Interior surfaces showcase the material's inherent texture—a fine mesh pattern resulting from fiber deposition on stainless steel screens—which absorbs residual moisture from fermented leaves during the first 72 hours post-packaging, preventing condensation that could compromise aromatic volatile compounds.

Controlled Breathing Mechanism for Aged Leaf Maturation

The lid-and-base construction of this molded pulp tea cake packaging incorporates a stepped interlock mechanism where the upper component's interior shoulder engages with the lower tray's raised perimeter ridge, creating a 2mm overlap zone that seals out airborne contaminants while allowing controlled gas exchange through microscopic pore channels. This breathing capacity proves essential for aged tea varieties requiring gradual oxidation—laboratory testing confirms the fiber matrix permits 0.18 liters of oxygen transmission per square meter daily, maintaining the enzymatic activity necessary for flavor maturation without exposing leaves to rapid degradation. Peacock feather illustrations rendered through water-soluble botanical pigments encircle the central product descriptor, their iridescent greens and blues achieved via layered mineral oxide application rather than petroleum-based inks, ensuring complete biodegradability within municipal composting streams.

Lifecycle Carbon Reduction Through Agricultural Residue

Transitioning from petroleum-derived canisters to this biodegradable box for tea reduces packaging carbon footprint by 68% across the product lifecycle, as sugarcane bagasse—a post-harvest agricultural residue—requires no virgin timber pulping or chemical bleaching. The molding process consumes 72% less water than comparable paperboard manufacturing, with production wastewater containing only organic solids that biodegrade in standard treatment facilities. Upon disposal, the entire assembly decomposes into humus-enriching compost within 90 days under industrial conditions or 6–8 months in backyard composting bins, leaving zero microplastic residues that could contaminate soil ecosystems. Embossed calligraphy along the polygonal edges adds tactile refinement, each character measuring 14mm in height to ensure legibility while maintaining the minimalist aesthetic that allows the product's natural beauty—both tea and packaging—to communicate quality without excessive ornamentation.

What We Mainly Make?

Eco Friendly Food Packaging

Custom structures for chocolates, macarons, dates, and biscuits. Food-grade biodegradable casings and partitions designed for gourmet gift presentation.

Eco Friendly Coffee Packaging

Premium all-paper canisters and gift set structures. Custom-fit kitting for beans and brewing accessories, blending artisanal craft with eco-conscious materials.

Eco Friendly Supplement Packaging

Reinforced molded pulp boxes and inserts for health kits. Structural kitting for bottles and powders that ensures safety while reflecting a pure, holistic brand.

Eco Friendly Gift Packaging

Premium lid-and-base molded pulp boxes with bespoke pulp inserts. Sophisticated, sustainable kitting designed to deliver a high-end and memorable unboxing experience.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

Public Mould

Public Mould

Packaging Solutions

Packaging Solutions

3D Design

3D Design

Customized Mould

Customized Mould

Round Lid Base Molded Pulp Box For Tea

Round Lid Base Molded Pulp Box For Tea

Polygonal Geometry Meets Fiber Precision Engineering

This sustainable tea cake packaging employs a precision-molded polygonal architecture that mirrors the geometric harmony found in traditional ceremonial vessels. The twelve-sided perimeter—each facet measuring 62mm in width—creates a softly angular silhouette that distinguishes premium compressed leaves from mass-market blends while maintaining structural integrity during stacking and transport. White bagasse fibers are wet-pressed at 4.2 MPa to achieve a uniform wall thickness of 3.8mm, generating sufficient rigidity to protect delicate pu-erh cakes from humidity fluctuations without requiring plastic lamination. Interior surfaces showcase the material's inherent texture—a fine mesh pattern resulting from fiber deposition on stainless steel screens—which absorbs residual moisture from fermented leaves during the first 72 hours post-packaging, preventing condensation that could compromise aromatic volatile compounds.

Controlled Breathing Mechanism for Aged Leaf Maturation

The lid-and-base construction of this molded pulp tea cake packaging incorporates a stepped interlock mechanism where the upper component's interior shoulder engages with the lower tray's raised perimeter ridge, creating a 2mm overlap zone that seals out airborne contaminants while allowing controlled gas exchange through microscopic pore channels. This breathing capacity proves essential for aged tea varieties requiring gradual oxidation—laboratory testing confirms the fiber matrix permits 0.18 liters of oxygen transmission per square meter daily, maintaining the enzymatic activity necessary for flavor maturation without exposing leaves to rapid degradation. Peacock feather illustrations rendered through water-soluble botanical pigments encircle the central product descriptor, their iridescent greens and blues achieved via layered mineral oxide application rather than petroleum-based inks, ensuring complete biodegradability within municipal composting streams.

Lifecycle Carbon Reduction Through Agricultural Residue

Transitioning from petroleum-derived canisters to this biodegradable box for tea reduces packaging carbon footprint by 68% across the product lifecycle, as sugarcane bagasse—a post-harvest agricultural residue—requires no virgin timber pulping or chemical bleaching. The molding process consumes 72% less water than comparable paperboard manufacturing, with production wastewater containing only organic solids that biodegrade in standard treatment facilities. Upon disposal, the entire assembly decomposes into humus-enriching compost within 90 days under industrial conditions or 6–8 months in backyard composting bins, leaving zero microplastic residues that could contaminate soil ecosystems. Embossed calligraphy along the polygonal edges adds tactile refinement, each character measuring 14mm in height to ensure legibility while maintaining the minimalist aesthetic that allows the product's natural beauty—both tea and packaging—to communicate quality without excessive ornamentation.

What We Mainly Make?

Eco Friendly Food Packaging

Custom structures for chocolates, macarons, dates, and biscuits. Food-grade biodegradable casings and partitions designed for gourmet gift presentation.

Eco Friendly Coffee Packaging

Premium all-paper canisters and gift set structures. Custom-fit kitting for beans and brewing accessories, blending artisanal craft with eco-conscious materials.

Eco Friendly Supplement Packaging

Reinforced molded pulp boxes and inserts for health kits. Structural kitting for bottles and powders that ensures safety while reflecting a pure, holistic brand.

Eco Friendly Gift Packaging

Premium lid-and-base molded pulp boxes with bespoke pulp inserts. Sophisticated, sustainable kitting designed to deliver a high-end and memorable unboxing experience.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

FAQs

Do you offer oil-proof solutions for greasy food products?

Does the packaging affect the taste or aroma of organic food?

How does pulp packaging help with food temperature retention?

Do you offer design services for custom packaging?

How long does molded pulp packaging take to biodegrade?

You may like

-

Round Shape Lid Base Bagasse Packaging Box Garment Food Packaging

Regular price $0.00Regular priceUnit price / per -

Pulp Packaging Mooncake Pastry Gift Boxes

Regular price $0.00Regular priceUnit price / per -

Molded Pulp Clamshell Egg Box

Regular price $0.00Regular priceUnit price / per -

Plant Fiber Sugarcane Pulp Chocolate Packaging

Regular price $0.00Regular priceUnit price / per -

Dyed Paper Mould Tea Bag Packaging Boxes

Regular price $0.00Regular priceUnit price / per -

Biodegradable Fried Food French Fries Packaging Box

Regular price $0.00Regular priceUnit price / per