Premium Black Finish for Tech Sophistication

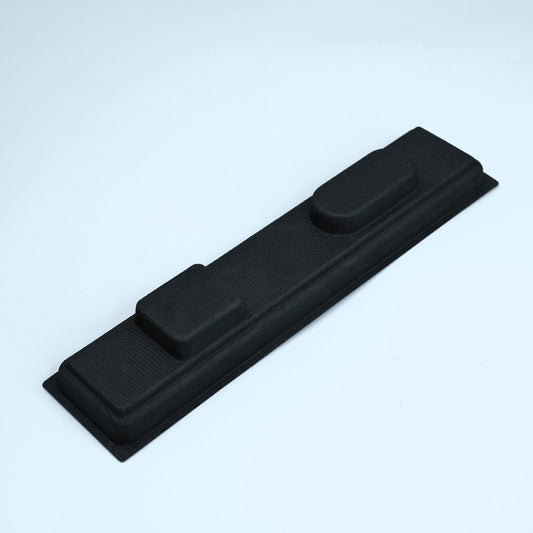

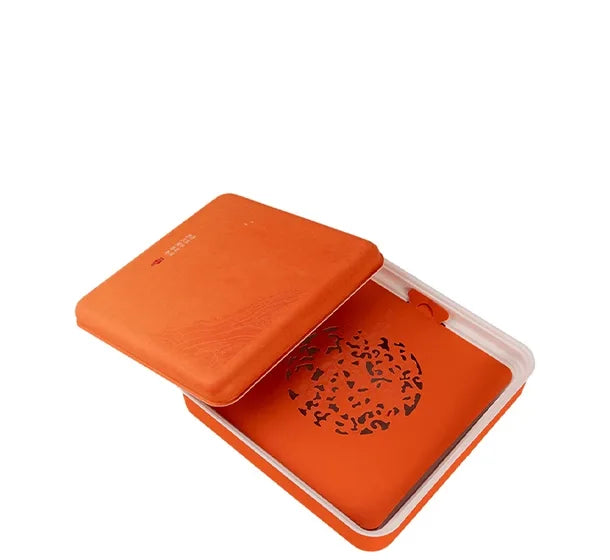

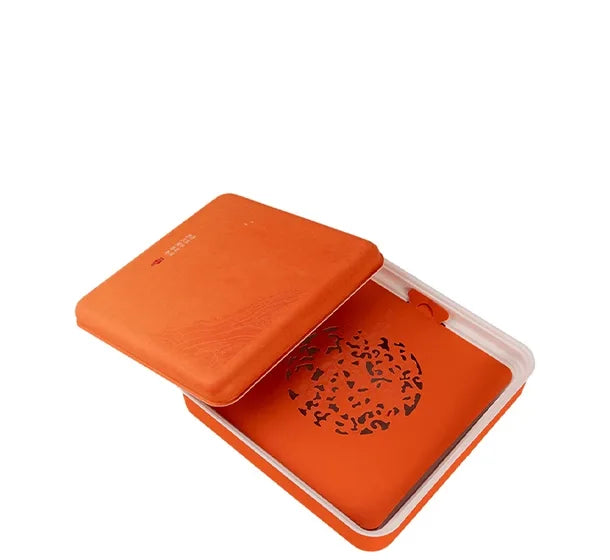

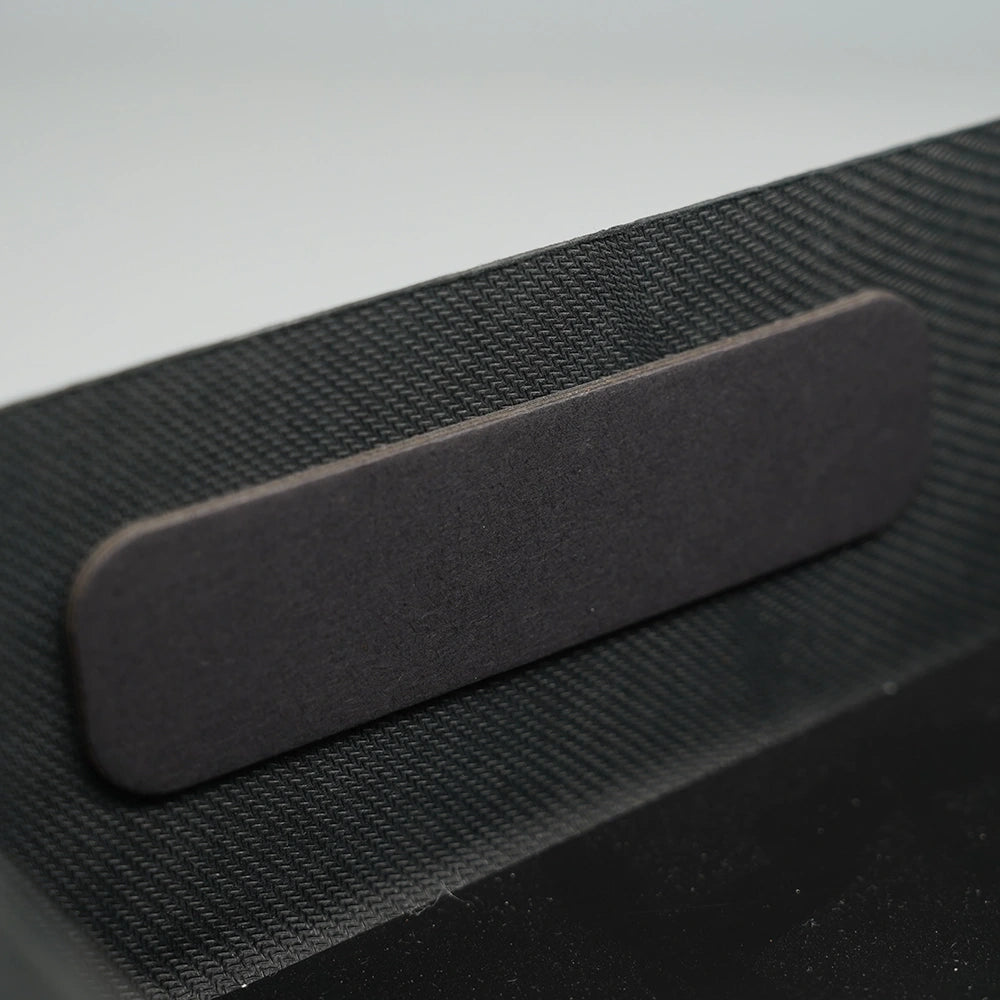

This black lid and bottom electronics gift box delivers a sophisticated aesthetic that complements high-end gadgets and digital accessories. The deep black coloring is achieved through specialized fiber dyeing during the pulping process, ensuring uniform pigmentation throughout the material rather than surface coating that chips or fades. The separate lid and base configuration allows for effortless access while maintaining a tight seal that shields sensitive electronics from dust and static buildup. Each cavity is precision-engineered to cradle devices securely, with anti-slip textures molded directly into contact points to prevent shifting during handling and transportation.

Plant-Based Strength for Digital Devices

Unlike petroleum-based foam alternatives, this sustainable electronics packaging is manufactured from renewable bagasse and bamboo fibers that naturally decompose after disposal. The thick-wall construction provides exceptional crush resistance, safeguarding circuit boards, screens, and charging ports from impact damage. Strategic ventilation channels molded into the structure prevent moisture accumulation that could corrode electronic components, while the material's inherent anti-static properties reduce electrostatic discharge risks. The two-piece design eliminates complex assembly steps, allowing manufacturers to streamline packaging workflows without sacrificing protective performance or presentation quality.

Customizable Architecture for Multiple Accessories

The versatility of this molded pulp electronics packaging extends to multi-component configurations, accommodating charging cables, adapters, instruction manuals, and warranty cards within dedicated compartments. Each section can be tailored with varying depth profiles and protective ribs to match specific product dimensions, eliminating movement that causes scuffing or scratches. The black finish accepts custom embossing, debossing, and hot stamping for brand logos and product specifications, transforming functional protection into a branded touchpoint. This fiber-based solution supports post-consumer recycling streams, breaking down into organic matter that enriches soil rather than persisting in landfills for centuries like traditional plastic inserts.

What We Mainly Make?

Eco Friendly Electronics Packaging

Molded pulp outer boxes and shock-absorbing inserts. A full-fiber kitting solution engineered to protect delicate gadgets with high-performance aesthetics.

Eco Friendly Gift Packaging

Premium lid-and-base molded pulp boxes with bespoke pulp inserts. Sophisticated, sustainable kitting designed to deliver a high-end and memorable unboxing experience.

Eco Friendly Houseware Packaging

Protective molded pulp tray and sturdy outer casings. Tailored for home essentials, ensuring superior structural integrity and eco-friendly brand positioning.

Eco Friendly Supplement Packaging

Reinforced molded pulp boxes and inserts for health kits. Structural kitting for bottles and powders that ensures safety while reflecting a pure, holistic brand.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

Public Mould

Public Mould

Packaging Solutions

Packaging Solutions

3D Design

3D Design

Customized Mould

Customized Mould

Black Molded Pulp Electronics Packaging

Black Molded Pulp Electronics Packaging

Premium Black Finish for Tech Sophistication

This black lid and bottom electronics gift box delivers a sophisticated aesthetic that complements high-end gadgets and digital accessories. The deep black coloring is achieved through specialized fiber dyeing during the pulping process, ensuring uniform pigmentation throughout the material rather than surface coating that chips or fades. The separate lid and base configuration allows for effortless access while maintaining a tight seal that shields sensitive electronics from dust and static buildup. Each cavity is precision-engineered to cradle devices securely, with anti-slip textures molded directly into contact points to prevent shifting during handling and transportation.

Plant-Based Strength for Digital Devices

Unlike petroleum-based foam alternatives, this sustainable electronics packaging is manufactured from renewable bagasse and bamboo fibers that naturally decompose after disposal. The thick-wall construction provides exceptional crush resistance, safeguarding circuit boards, screens, and charging ports from impact damage. Strategic ventilation channels molded into the structure prevent moisture accumulation that could corrode electronic components, while the material's inherent anti-static properties reduce electrostatic discharge risks. The two-piece design eliminates complex assembly steps, allowing manufacturers to streamline packaging workflows without sacrificing protective performance or presentation quality.

Customizable Architecture for Multiple Accessories

The versatility of this molded pulp electronics packaging extends to multi-component configurations, accommodating charging cables, adapters, instruction manuals, and warranty cards within dedicated compartments. Each section can be tailored with varying depth profiles and protective ribs to match specific product dimensions, eliminating movement that causes scuffing or scratches. The black finish accepts custom embossing, debossing, and hot stamping for brand logos and product specifications, transforming functional protection into a branded touchpoint. This fiber-based solution supports post-consumer recycling streams, breaking down into organic matter that enriches soil rather than persisting in landfills for centuries like traditional plastic inserts.

What We Mainly Make?

Eco Friendly Electronics Packaging

Molded pulp outer boxes and shock-absorbing inserts. A full-fiber kitting solution engineered to protect delicate gadgets with high-performance aesthetics.

Eco Friendly Gift Packaging

Premium lid-and-base molded pulp boxes with bespoke pulp inserts. Sophisticated, sustainable kitting designed to deliver a high-end and memorable unboxing experience.

Eco Friendly Houseware Packaging

Protective molded pulp tray and sturdy outer casings. Tailored for home essentials, ensuring superior structural integrity and eco-friendly brand positioning.

Eco Friendly Supplement Packaging

Reinforced molded pulp boxes and inserts for health kits. Structural kitting for bottles and powders that ensures safety while reflecting a pure, holistic brand.

Why Choose Molded Pulp Packaging?

No Plastic, Eco-friendly

Protecting the environment and caring for animals and plants is to maintain ecological balance and safeguard the human living environment.

Biodegradable And Recyclable

Made from raw wood pulp and sugarcane pulp, it is recyclable and decomposable.

Stackable, Lightweight, And Low Shipping Costs.

The shipping costs are lower than foam, vacuum forming, pearl cotton, etc. Products can be stacked, saving storage and transportation costs.

Anti-static, Waterproof, And Moisture-Proof

The pulp contains fiber tissue, effectively protecting the carried items.

Customizable In Various Shapes And Colors

Compared to other packaging, molded pulp packaging is customizable, allowing you to create packaging in any shape and color according to your product.

Customizable Process

01

Design products based on the customer's ideas, or it's even better if the customer can provide a 3D format.

02

Provide customized solutions based on customer information.

03

Affirm the design proposal by the client.

04

Receive the objective product from our client.

05

Verify the product size and make the production mold.

06

Confirm the sample made by the mold and proceed with mass production.

FAQs

Can I fit cables and accessories into a single pulp tray?

Can molded pulp replace EPE foam for heavy electronic devices?

Does the material produce dust that could damage ports?

What industries do you serve with molded pulp packaging?

Can I add my brand logo directly onto the eco-friendly material?

You may like

-

Eco-Friendly iPad Biodegradable Bamboo Pulp Inner Tray

Regular price $0.00Regular priceUnit price / per -

Sustainable Smartphone Case Elegant Packaging

Regular price $0.00Regular priceUnit price / per -

Sustainable Black Paper Molded Insert Tray For Daliy Use

Regular price $0.00Regular priceUnit price / per -

Sustainable Smartwatch Molded Pulp Insert For Wristwatch

Regular price $0.00Regular priceUnit price / per -

Pulp Molded Paper Tray Packaging for Earphones Set

Regular price $0.00Regular priceUnit price / per -

Biodegradable Custom Pulp Molded 3C Products Packaging

Regular price $0.00Regular priceUnit price / per